Växellåda och drivlina

- Övrigt

Dokument - Transmission ID Charts

Automatic Transmission ID Chart

Download Automatic Transmission ID Chart

Manual Transmission ID Chart

Download 3, 4, 5, & 6-Speed Manual Transmission ID Chart

Dokument - Hurst Stick Diagrams

Hurst Flat Bar Shifter Stick Diagrams

Download Hurst Flat Bar Shifter Stick Diagrams

Hurst Round Bar Shifter Stick Diagrams

Download Hurst Round Bar Shifter Stick Diagrams

Dokument - Discontinued Shifter Stick Diagrams (For Reference Only)

How to Choose a Clutch

Quick Time Bellhousings

Lakewood Bellhousings

Supportbibliotek från Holley - YouTube-klipp

Supportbibliotek från Holley - Artiklar

FAQ's - Clutches

|

Question |

What is the difference in the Borg & Beck, Diaphragm and Long-Style pressure plates? |

|

Answer |

The Diaphragm style is a multi-finger plate that takes less pedal pressure to release. The Borg & Beck and Long-Style are 3 finger plates that provide a higher clamping force. |

|

Question |

Should I use an aluminum or steel flywheel? |

|

Answer |

Aluminum flywheels with their lighter weight, are typically used in oval track and road race applications and are also popular in high-horsepower, light weight drag cars. These vehicles rely on engine horsepower to drive the wheels. Steel flywheels are used in applications that require additional engine torque for performance. A heavier flywheel can help acceleration from a standing start and keep the engine's RPM and power up through shifting. These are characteristics needed in street, most drag race and other high-torque applications such as tractor pulling. |

|

Question |

What is the difference between Neutral (internal) Balance and Detroit (external) Balance Flywheels? |

|

Answer |

Neutral (internal) Balance engines and flywheels are each balanced as an individual unit. In other words, the engine and flywheel are in balance with or without the flywheel mounted to the crankshaft. A Factory Balanced (external), or Detroit Balanced engine uses the flywheel to balance the engine assembly. With the flywheel off of the engine, both the engine and flywheel are out of balance. |

|

Question |

What Hays flywheel do you recommend for my engine and what size Hays clutch can I use with it? |

|

Answer |

Hays offers stock size and weight as well as custom applications built to order. |

|

Question |

Why can't I get my clutch to release and shift properly after it is completely installed? |

|

Answer |

This is typically means the clutch needs adjustment. Adjustment procedures vary by vehicle and can be found in most service manuals. |

|

Question |

Which clutch kit to you recommend for my street/strip muscle car? |

|

Answer |

Street/strip clutches are available for most applications and can be found in our Hays catalog. |

|

Question |

Why do I need to use a SFI-certified steel flywheel instead of a cast iron flywheel? |

|

Answer |

High performance applications must meet elevated performance requirements. |

|

Question |

How much static pressure clamp force do your Hays clutch pressure plates give out? |

|

Answer |

Street applications are rated up to 2,400 lbs and street/strip applications are rated up to 2,750 lbs. |

|

Question |

Should my new Hays Clutch be balanced before installation? |

|

Answer |

No, all Hays pressure plates and flywheels are dynamically balanced to extremely close tolerances. However, if you are having an engine assembly re-balanced, it would be a good idea to include the clutch components to insure tolerances be as tight as possible. |

|

Question |

What is static pressure? |

|

Answer |

Static pressure, also referred to as base pressure, is the amount of spring pressure (in pounds per square inch) that is exerted by the pressure ring to the clutch disc when the clutch is engaged. |

|

Question |

What is centrifugal or roller assist? |

|

Answer |

Certain Hays pressure plates feature centrifugal assist for increasing pressure plate load to prevent slipping and high RPM plate/disc separation. The Borg & Beck design utilizes rollers inside the cover that are forced to the outside under centrifugal force to increase plate load as RPM increase. Certain Long-Style pressure plates use levers that have extra weights on the levers to provide centrifugal assist. |

|

Question |

Can you install a clutch disc backward? |

|

Answer |

We receive returned discs for warranty that are installed inside-out and bent when a customer tries to put the disc in backward. With the flywheel installed on the engine, lay the clutch disc on the flywheel and rotate it some. It must sit flat against the flywheel and not be contacting the flywheel bolts as you rotate it. If the disc does not sit flat, make sure you have it in correctly. |

|

Question |

Can I use power tools to tighten the pressure plate? |

|

Answer |

We do not recommend this. Tightening down the cover puts a load on the clutch cover flange since you are pulling it down against the pressure of the diaphragm or coil springs. Using power tools can cause this flange to bend which will leave the fingers uneven once the clutch is fully tightened down. This can cause extreme clutch chatter. |

|

Question |

Which clutch kit to you recommend for my street/strip muscle car? |

|

Answer |

We offer our Hays Classic, Street 450, or Street 650 for most street/muscle car applications. Please see in our Hays website. |

|

Question |

Do I need to make sure I have proper release bearing adjustment? |

|

Answer |

Yes, setting the proper release on your clutch is very important — not only initially, but periodically going forward. A mechanical linkage should be adjusted for minimum release; that is only enough release that the clutch will disengage cleanly for shifting. This will result in a pedal lower to the floor and leave maximum free play. As the clutch disc wears, the fingers of the clutch will get taller, and if you have the bearing adjusted too close, it could ultimately unload the clutch fingers and not let the plate put its full load on the disc. This will cause undue slippage and wear. This applies to mechanical or cable type clutch linkage. |

|

Question |

My flywheel looked pretty good so I just went ahead and installed the clutch. Do I have to resurface my flywheel before a new clutch install? |

|

Answer |

We have been asked this many times. No matter how good the surface may look, if you want the new clutch to seat properly, it needs a fresh friction surface to seat against. |

|

Question |

Can I just change out the clutch disc only? |

|

Answer |

Obviously the clutch disc is the part of your system that will physically wear the most. Changing only the disc is setting yourself up for problems. As the clutch, disc, and flywheel wear in, the surfaces build a taper that the clutch disc will conform to. If you install only a disc, it is going to make contact on the outer edges only and will never properly seat. Ultimately this will cause premature slippage and will most likely chatter on takeoff. |

|

Question |

What starter do I use with Hays flywheels? |

|

Answer |

Most starters use stock or stock style unless otherwise specified. |

|

Question |

How should I adjust my clutch? |

|

Answer |

First of all, be sure all mounting fasteners are torqued correctly, this is very important. The actual adjustment will vary depending on the type of pressure plate being used. With the clutch pedal completely depressed, a diaphragm should have .030-.040 air gap between the disc and flywheel, for a Borg & Beck the air gap should be .040-.050 and for a Long-Style pressure plate it should be .050-.060. On vehicles with mechanical linkage, with the pedal released, an air gap of .250” should exist between the throwout bearing face and pressure plate fingers. On cable and hydraulic applications, the throwout bearing face should rest lightly on the pressure plate fingers. |

|

Question |

Can I tighten my pressure plates bolts down all the way 1 at a time? |

|

Answer |

No we do not recommend this. A way to damage the flange of the clutch cover is to tighten the bolts down completely in one shot instead of in a star-shaped pattern. This can damage the flange and also cause the fingers to sit unevenly. Tighten the cover bolts ONLY with hand tools, and use a star-shaped or crisscross pattern, a few turns at a time, just like torquing your wheels in place. |

FAQ's - Shifters

|

Question |

What is the difference between the Hurst Competition Plus shifter and the Street Super Shifter? |

|

Answer |

While both shifters use the same legendary Hurst mechanism, the Competition Plus uses mounting hardware and an appropriately shaped stick handle to locate the shifter into the vehicle’s stock location or console. The Super Shifter is a “no holds barred” shifter, and uses straight linkage rods to minimize rod flex during hard shifts. The Super Shifter makes no modifications to the mounting hardware and will not fit into factory consoles; they typically mount high and at the end of the tailshaft to use the straight linkage rods. Super Shifter also utilizes a short 7 1/2 inch stick to keep the throws as short as possible. |

|

Question |

I would like to add a T-Handle to my Hurst shifter. What thread size do I need? |

|

Answer |

Although there are some exceptions, nearly all chrome- plated steel sticks used on aftermarket Hurst shifters are 3/8 x 16. Aluminum, black aluminum, or black steel sticks (late model Mustang and Quartersticks) are 7/16 x 20. Older Hurst OEM shifters are 3/8 x 24. One exception to this is the T-56 six speed shifter. While the chrome stick version is 3/8 x 16, the black stick version is 16mm x 1.5 to fit the factory knob only. |

|

Question |

Do you still make Hurst Lightning Rod automatic shifters? |

|

Answer |

NO. At this time we only manufacture Lightning Rods for the 4 & 5 speed Lenco transmissions. Parts are no longer available for Hurst Lightning Rod automatic shifters. |

|

Question |

I have all of the factory numbers off of my transmission, can you tell me what it is and what it came out of ? |

|

Answer |

Unfortunately, it would be impossible for us to have listings for all of the different years and types of OEM transmissions by part number. What we have done is put pictures of the various 3 and 4 speed transmissions, as well as automatics, in the back of the Hurst catalog. Below each picture is a 3 digit identification number which can be used to determine the correct shifter and installation kit for your application. |

|

Question |

I have often wondered what the difference is between the nylon and steel bushings you offer in the Hurst Pit Pack. Steel is better right? |

|

Answer |

Maybe not, the steel is stronger then nylon, but with nylon you do not get the harsh rattle noise on highways with a softer tone ,it makes life a bit more pleasant. Now on the other hand, if you are a hard core racer, you may want the stronger bushings while going down the track for that trophy. |

|

Question |

I’m trying to install a Hurst shifter into my ’55-57 Chevy, but it seems like the stick is going to be under the bench seat. |

|

Answer |

For ’55-57 Chevys, Hurst uses a special stick shaped like a large “C” to clear the original bench seat. Due to the extreme angle that the stick comes out of the mechanism, it was not possible to make it a bolt-on stick. It is welded into the mechanism, like the 65-70 Mustang shifter. The stick is not available separately, and can only be ordered with the shifter under part # 3913780. |

|

Question |

I’m trying to install a Hurst shifter into my ’67 Mustang, but the reverse linkage interferes with the crossmember. What do I do? |

|

Answer |

To install a shifter into the stock location, Hurst created a shifter that mounts cocked towards the rear of the car; towards 2 O’clock. It incorporates a unique lower reverse lever in the mechanism to clear the crossmember. To compensate for the mechanism being mounted on an angle, the chrome stick is welded into the mechanism in the opposite direction to properly locate the handle in the vehicle. The stick and mechanism are not available separately, and are only sold under part # 3913180. |

|

Question |

I would like to get the stick from my OEM shifter re-chromed. How do I get the stick out of the mechanism? |

|

Answer |

OEM shifters used a “bayonet-style” stick, held in with two metal clips and rubber isolators on each side of the stick. To remove the stick, place or push a steel shim or feeler gauge down each side of the stick, at the bottom where the chrome handle goes into the mechanism, and pull. Should you need new clips and isolators, they are available through your nearest Hurst retailer or through Hurst for a nominal charge. |

|

Question |

Why doesn’t my new Hurst Competition Plus fit my OEM linkage? My car originally came with a Hurst Shifter. |

|

Answer |

Hurst originally supplied only the shifters to the big three – made to their specifications. Hurst did not supply the linkage. OEM linkage is frequently smaller in diameter and/or the shifter is mounted in a slightly different location, making the Hurst aftermarket shifters and linkage incompatible with OEM shifters, linkage and mounting plates. |

|

Question |

My shifter jams or hangs up in gear. What is the problem? |

|

Answer |

First, check to see if the linkage rods are encountering any interference. With the engine off and the parking brake engaged, have a friend operate the shifter and observe the linkage rods to see that the rods operate freely. Second, check to see if the transmission arms have become elongated (wallowed out). This may cause incomplete travel. Be sure that the linkage rods are parallel to the shifter lever’s travel. If they are “crooked” it may cause binding. Finally, the mechanism may be in need of a rebuild. Although made for years of outstanding performance, the shifter may require a rebuild after several years of use or severe duty. See the rebuild information below should you require this service. |

|

Question |

What should I use to lubricate my new Hurst Shifter? |

|

Answer |

Hurst shifters are pre-lubricated at the factory. It is not necessary to oil the mechanism or grease it, as this will attract dirt and cause premature wear of the mechanism. The only exception is an internal rail shifter (such as the T-5 and T-56 models). A light coat of grease to the pivot ball tip on the bottom of this shifter prior to installation will help avoid premature wear. Be sure to seal internal rail shifters to the transmission with a thin bead of silicone RTV. |

|

Question |

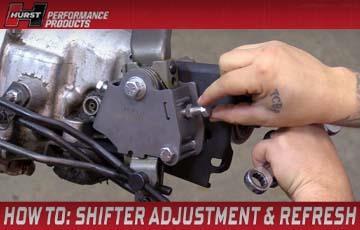

What is the proper way to adjust my Hurst four speed shifter? |

|

Answer |

There is a 1/4 inch hole at the bottom of the Hurst mechanism that runs through all three levers. This is called the neutral alignment hole. To ensure proper adjustment, run the shifter from first into second and then back to neutral. Insert the neutral alignment pin (or a 1/4 inch drill bit) into the neutral alignment hole. If the 1-2 lever interferes with the smooth insertion of the alignment pin, remove the 1-2 linkage rod from the shifter and thread the adjuster button either in or out to eliminate the interference. Repeat this procedure with the 3-4 lever and reverse. To adjust the stop bolts, back the bolts out of the shifter frame until only a few threads remain. Push the stick firmly into third gear and hold. Screw in the stop bolt until contact is made. Release the stick and back the stop bolt out one turn and tighten the jamnut. Push the stick into fourth gear and repeat the procedure. |

|

Question |

I’m having difficulty getting my automatic shifter adjusted to properly engage all the gears. |

|

Answer |

Some Hurst shifters are universal in design (particularly Pro-matics and V-matics). Some applications, usually Ford and Chrysler, require more exact adjustment than others. Try adjusting the cable pivot in either Low or Neutral, just be sure both the shifter and transmission are in the same gear when adjusting. |

|

Question |

What does “not for COE” stand for? |

|

Answer |

Packaging for Hurst Indy pick up truck universal shifters states “not for COE”. Our Technical Service Department has received numerous, and interesting, guesses. Some of the best are Computer Operated Engine, Canadian Only Engine, and Clutch On Engine. The correct meaning is not for Cab Over Engine.Helpful? |